Whether you are prepared for them or not, power interruptions can cost your business more than you think. Not all power disruption costs are evident right away, and better cost-awareness helps justify preventive measures. So, let’s get into some power-disruption sources, cost impacts, and a way to help avoid them.

Understanding diverse sources of power disruption

Weather events including storms, lightning strikes, and high winds are the leading causes of outages, and this unpredictability can seriously impact power-grid reliability, both short- and long-term. Other factors like aging infrastructure, equipment failure, and cyberthreats make it complicated to protect the grid today. Now, add today’s increasingly electricity-intensive technologies and drive to electrification to the mix. From electric vehicles (EVs) to air conditioners, we are looking at the kind of grid strain that can cause overload, resulting in even more power outages.

But aside from total power outages and interruptions, disruptions to your energy systems can occur in several other ways. These disruptions are not usually as noticeable as full outages, and they include:

- Momentary power interruptions from temporary faults in electrical distribution (from less than a second to a few seconds)

- Inconsistencies in voltage, known as sags, surges, or swells of power

- A persistent low power factor (a given system’s energy efficiency)

Power-quality and grid-distribution issues like these can cause equipment shutdown, decreased performance, data loss, and processing problems at your facility. They can also reduce the efficiency and longevity of electrical assets over time, resulting in additional utility charges and facility infrastructure costs.

The cost implications of power disruption

There are many cost repercussions for facility power disruptions. Some costs are transparent to facility managers; others may turn up later. Total power outages are typically the most obvious and costly power disruptions as they often bring operations to a standstill. The longer an outage lasts the greater the ripple effects will be — of lost time, lower productivity, and impacted revenue.

For instance, when data centers suffer downtime from outages, it can cost businesses an average of $9,000 per minute 1. In high-risk industries — like healthcare, manufacturing, and transportation — outages disrupting data centers can lead to some $5 million per hour.1 Larger industrial facilities with multiple megawatts (MW) of demand say a momentary interruption of even less than five minutes can cost at least $50,000.2

Another example is the cement industry. Cement manufacturing sites experience outage costs differently during that downtime. A short-duration outage, in minutes to a few hours, may cost around $30,000 due to the thermal mass of the kiln and other equipment used to produce cement. But if the outage is extended and equipment cools, the cost skyrockets to the hundreds of thousands of dollars and carries a significant recovery period to clean hardened material, restart the process, and account for a finished product that was not sold. Here, a multi-hour shutdown can easily turn into a multi-day headache to get back to normal operations.3

Poor power quality is often an imperceptible issue in the moment, but can damage machinery and energy equipment, forcing businesses to replace equipment far earlier than anticipated, straining operational and capital budgets. Power sags and surges can also add to equipment damage, cause equipment to reset, or simply cause failure.

Production losses are a simple way for many industrial customers to determine outage costs. However, that may not capture the full picture, and there exist other types of facilities that do not produce a tangible or quantifiable product. How might power disruptions be translated into an opportunity cost?

- Customer service and satisfaction

- Salary losses and employee morale

- Insurance costs

- Equipment damage and spoilage

- Public opinion and marketing power

These categories are a bit more qualitative but can have a real impact on the bottom line. How does the perception of unreliable power decrease customer revenue? How do outages impact inventory management or the delivery of goods throughout the supply chain? How might insurance costs react to missed contractual deliveries of goods? How much time is lost re-starting technology and recovering lost data? How does future electrification of vehicles and other systems impact the ability to provide service to customers? These questions can be translated into costs that drive solutions.

Avoiding power outages and their costs

Microgrids are one of the best solutions to on-site power disruptions. Microgrids are local energy systems with sources of power generation, storage, and advanced controls that directly integrate with the customer’s electrical system. They function with the utility grid, or more important, independently from it when needed.

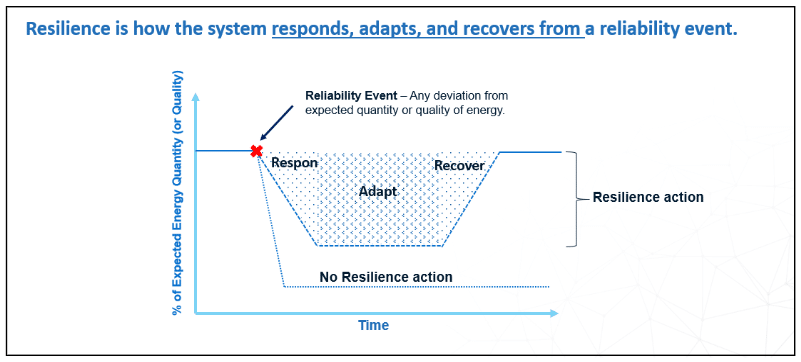

This means that when the grid experiences any sort of interruption, microgrid assets can pick up the site’s energy load to keep it all in operation without a hitch. This allows microgrids to deliver resilience and reliability through a power-supply experience that is not possible with grid-reliance alone. Microgrids can also improve the quality of the power at a site, avoiding damaging surges and frequency issues. This means that microgrids can help businesses enhance the reliability of their existing grid connection, mitigating a diversity of power-quality issues and costly surprises.

Since microgrids can operate autonomously and in parallel to the grid, they are a strong defense against unseen outage costs. Local, on-site generation is more efficient, avoiding transmission and distribution losses. Last, the relevance of microgrids grows in the era of decarbonization, providing low/zero emission power, and reducing local and global emissions.

Want our help in figuring out how much outages and downtime cost your business? Email us at: info@alphastruxure.com

- Sullivan, Schellenber, Blundell, Updated Value of Service Reliability Estimates for Electric Utility Customers in the United States, 2015