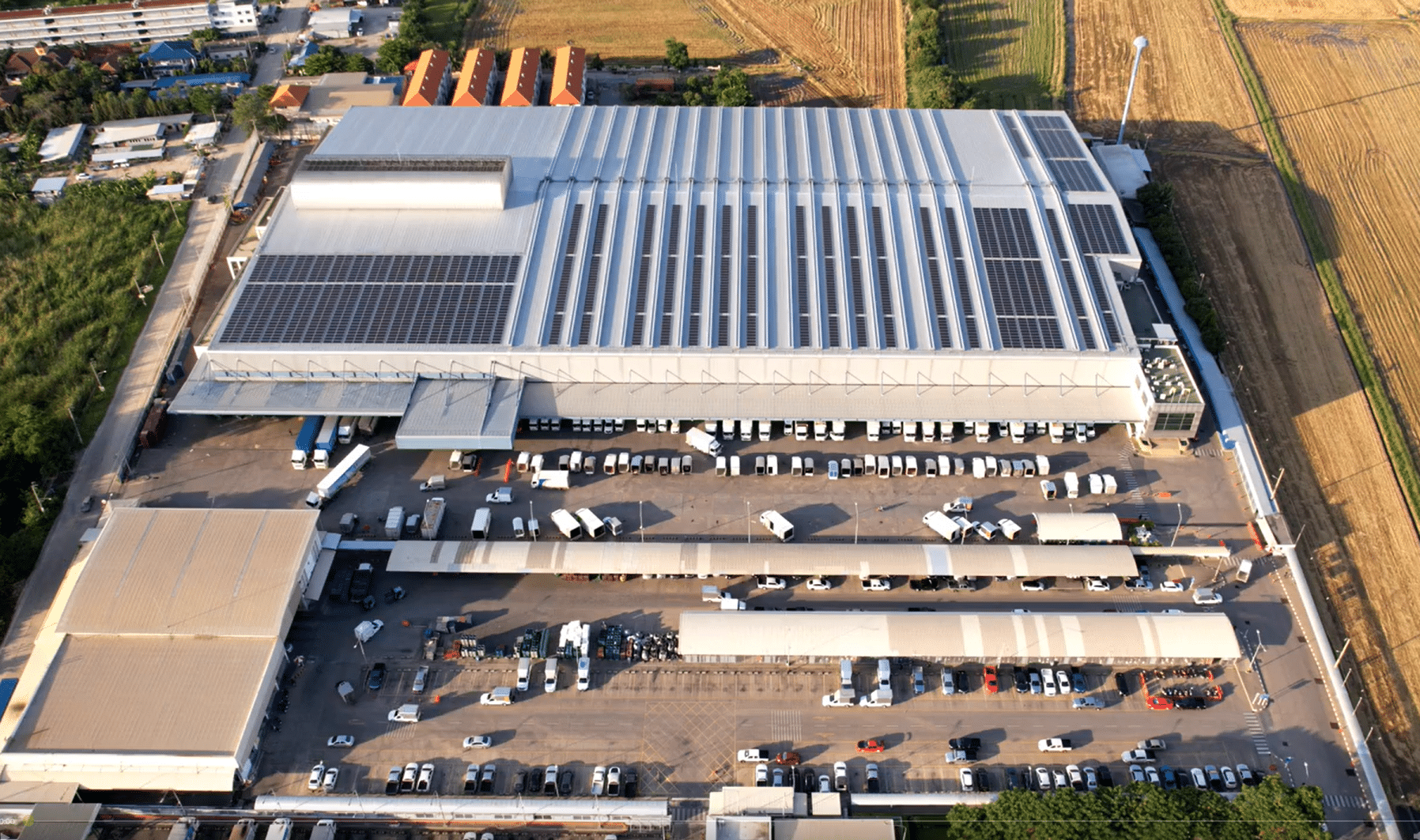

There is no question that large microgrids for commercial and industrial customers are complex systems. From development and conceptualization of the solution to the design-build stage to the long-term operations and maintenance of the system to meet performance requirements, there are many sophisticated workflows along the way.

So how can energy stakeholders realize a microgrid’s undeniable energy-related promises and payoffs?

Figuring out the site’s energy requirements, peak demand, performance indicators, and power quality takes data, analytics, and data insights to make the most of the microgrid. This initial, rather laborious effort is well worth it, of course, for the long-term performance benefits and sustainability outcomes. Not only do microgrids deliver the innovative use of renewable energy they also deliver unprecedented flexibility in energy demand for the customer and the grid.

This upfront commitment to fine-tuning the system will unlock all the benefits of microgrids: measurably changing the way existing buildings and industrial facilities consume energy while also curtailing greenhouse gas emissions. Indeed, microgrids ultimately enable energy stakeholders to realize net-zero emissions goals over the long life of a building or facility.

Bringing a microgrid site online is a lot like getting a puppy or adopting a dog. A bit of uncertainty. A lot of chaos. A few puddles. Optimal performance takes some time. After a few months, though, you ultimately find a consistent rhythm. That’s the turning point when you and Maxie become happy campers who know precisely what makes each other tick. Just like your beloved dog who senses when it’s time for a walk even before you get your shoes on, a digitally enabled smart microgrid loves repetitive, predictable behavior.

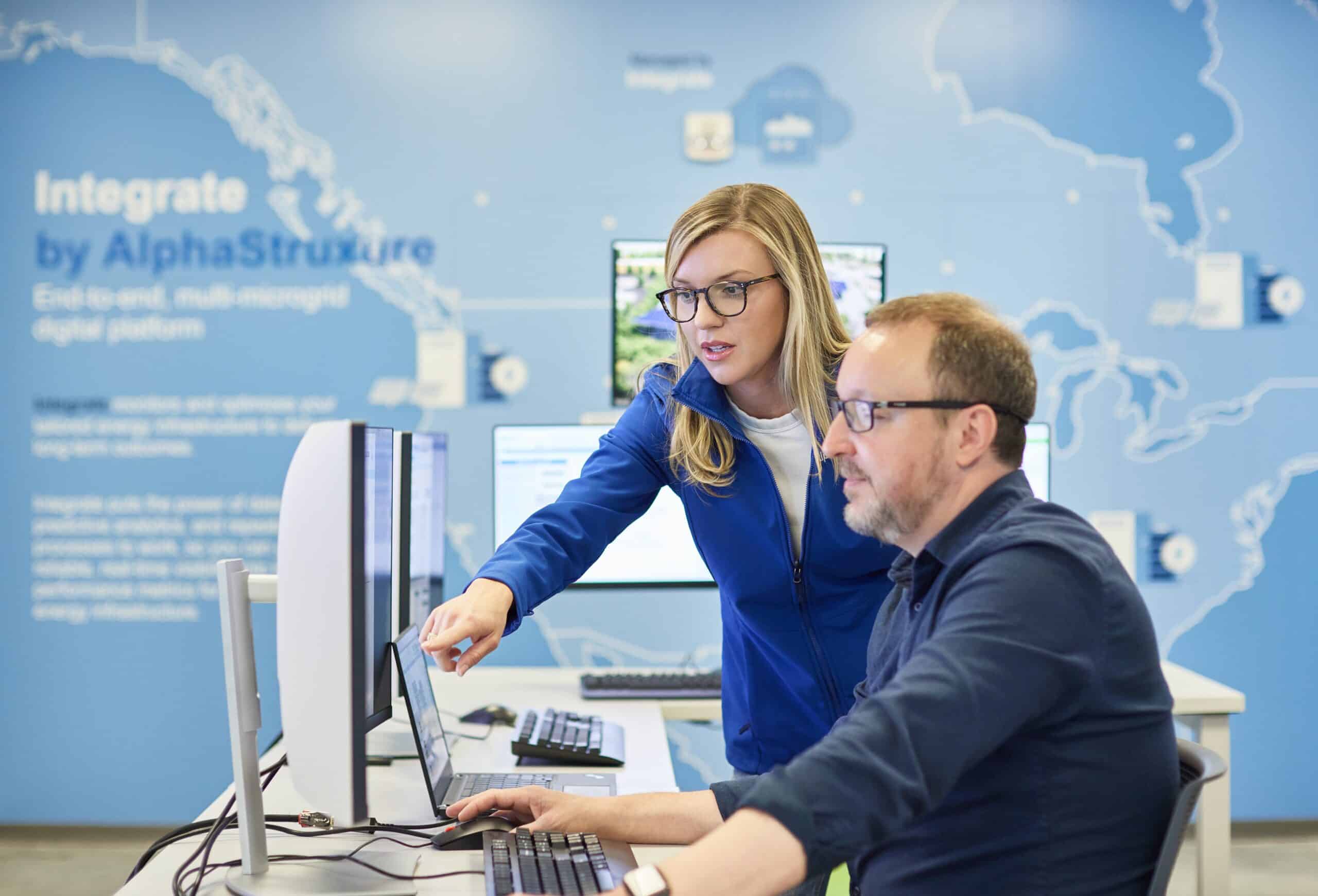

Digitalization: the key to fine-tuning the microgrid

Digitalization is the key to establishing optimized and reliable microgrid performance. Digitalization unlocks valuable data, uses that data for trending and analytics, conducts remote and automated operations, efficiently integrates workflows across disparate systems, and easily creates information sharing among stakeholders.

How does this work in practice? The AlphaStruxure Integrate Digital Platform for example is a digital backbone that provides real-time visibility of a microgrid’s performance to all energy stakeholders at any time, allowing for optimal operations throughout the site’s lifecycle.

By compiling and analyzing data across the on-site energy infrastructure, the platform delivers continuous performance insights that can ensure consistent operational processes and maintenance. With the power of digitalization, organizations can rely on Integrate to deliver key metrics to achieve long-term outcomes on energy cost predictability, energy resilience and reliability, and greenhouse gas reduction.

For organizations looking to meet aggressive energy and sustainability objectives with on-site energy infrastructure, it’s important to have a platform geared to tracking measurable progress toward those objectives and then trending all that information to learn from the data — not just data for data’s sake but data with a purpose. With the expanded use of data, performance trending, predictive analytics, and information sharing, organizations can observe the direction and magnitude toward achieving specific goals.

In short, manual log keeping simply just doesn’t meet these needs. It’s time to teach the old energy dog new tricks, thanks to digitalization.