Laid out in President Biden’s $2 trillion American Jobs Plan is a focus on revitalizing U.S. manufacturing, fortifying the electric grid and accelerating the development and adoption of clean energy technologies. These initiatives are interconnected; increasing the global competitiveness of the U.S. manufacturing sector hinges on overcoming the energy-related challenges that the industry faces.

While the administration’s plan is a huge step in the right direction, the manufacturing industry needs to take its own action. Forward looking organizations are thinking about energy as a key factor in their market competitiveness and seeking solutions to overcome the capital and risk barriers that come with energy infrastructure upgrades.

Energy challenges: Reliability & resilience

As the most energy-intensive industry, manufacturers are acutely aware of the impacts of our aging power grid. Even a microsecond of an outage or a small fluctuation in power quality can result in equipment shutting off, wasted product, equipment damage and additional downtime getting processes back up and running. Out of all the industries impacted by power outages, manufacturers are often hit the hardest, with as much as $150,000 in damages per facility in a year.

Along with outdated energy infrastructure, the uptick in extreme weather events is adding fuel to the fire. In 2020, there were 22 separate “billion-dollar” weather and climate disasters, eclipsing the previous annual record of 16 events. Damage in the last five years alone exceeds $600 billion. It’s undeniable: today, energy reliability and resilience is critical to manufacturing organizations’ bottom line. If a company isn’t profitable, it can’t expand and train its workforce, invest in R&D, or compete on a global scale — all key components of Biden’s plan to revitalize the manufacturing sector.

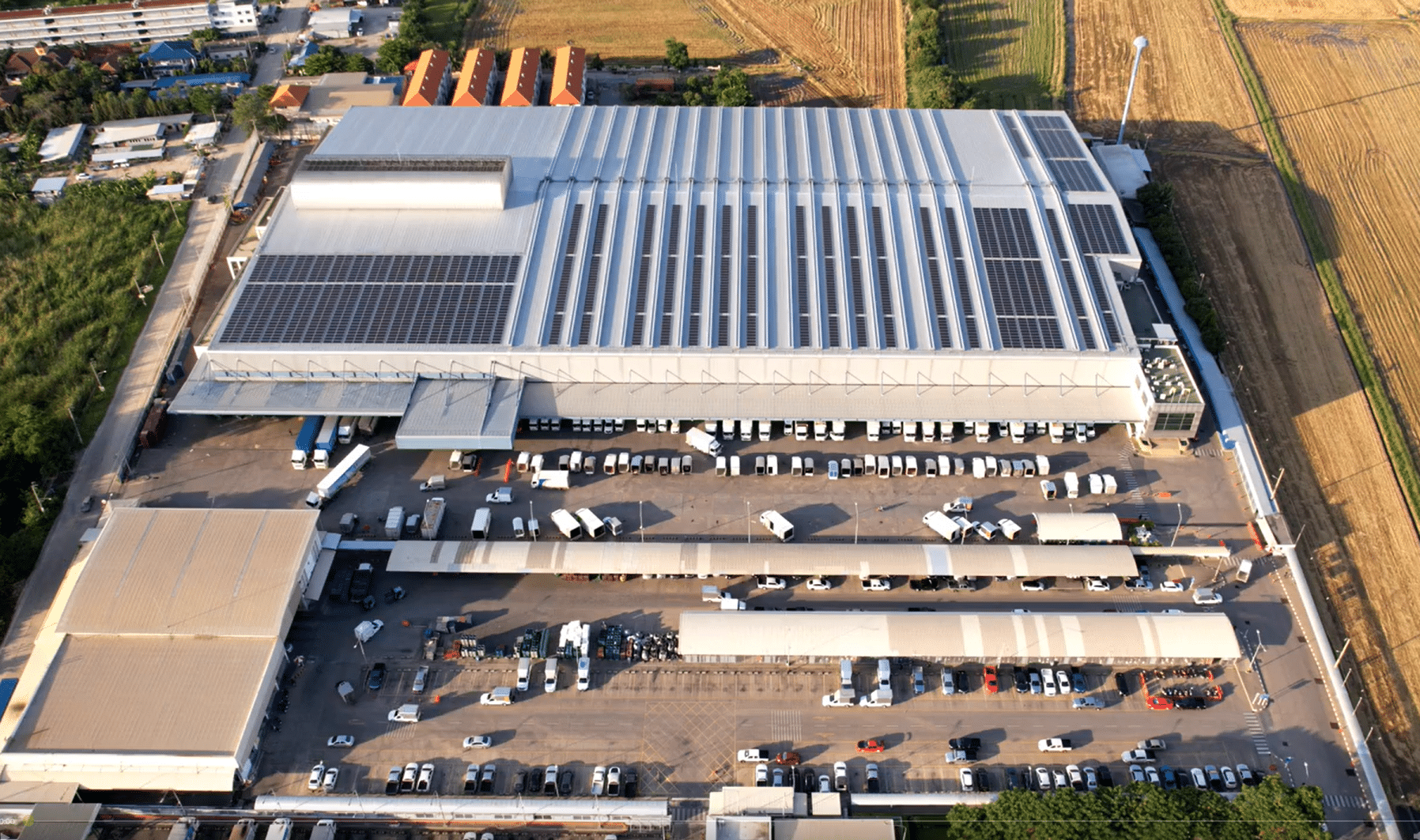

Many manufacturers are turning to microgrids to maintain power quality and eliminate the many short duration outages and power quality issues that impede productivity. A microgrid is a self-contained electrical network made up of distributed energy resources like wind turbines, solar panels, fuel cells, batteries, and other technologies which can operate in concert with or independent of the utility grid. Not only does this ensure operations stay up and running during utilities’ power outages, it eliminates power quality disruptions and helps organizations save money through utility demand charge management.

Energy challenges: Sustainable supply chain mandates

In line with the Paris Climate Accord, hundreds of large, publicly traded companies have pledged to reduce or eliminate greenhouse gas (GHG) emissions from their own facilities (Scope One), source renewable energy for electricity needs (Scope Two) and to address indirect emissions in their supply chain (Scope Three).

According to Rocky Mountain Institute, global industrial supply chain emissions account for 40 percent of annual GHG emissions. Although companies don’t have direct control over their suppliers, the Science-Based Targets initiative stipulates that a company must take accountability for Scope Three emissions if they add up to more than 40 percent of the combined Scope One, Two and Three emissions.

As a result, a growing number of the world’s largest companies from PepsiCo to Wal-Mart are putting pressure on their suppliers to lower GHG emissions and engaging them in climate action and solutions. If manufacturers are to keep their customers and remain competitive on the market, they have to follow suit. Sustainability is no longer just nice to have, it’s a business imperative.

The manufacturing industry comprises more than 60% of total industrial emissions in the U.S., and is on track to becoming the country’s largest source of GHG emissions within the next ten years. The majority of these emissions come from a subsector of manufacturers whose production processes rely on thermal energy, such as chemicals, iron, steel, cement, aluminum, glass and paper.

These sectors aren’t able to decarbonize their operations entirely through upgrades to their existing electrical network. This is an area where distributed energy resources can also help. With an on-site microgrid, manufacturers are able to source and integrate new low-carbon fuels and other forms of onsite renewable energy generation to reduce GHG emissions while fortifying their operations with reliable, resilient energy.

Who’s going to pay for it?

The $2 trillion infrastructure plan is a drop in the bucket in terms of what is required to truly modernize U.S. manufacturing infrastructure. According to recent studies, it could cost up to $2 trillion by 2030 just to maintain current levels of utility grid reliability, which are not adequate today, let alone in a changing climate.

To accelerate efforts around fortifying U.S. manufacturing operations and market competitiveness, manufacturers can bring in a third-party Energy as a Service (EaaS) provider to design, build, own, operate and maintain custom microgrids at no upfront capital cost. Similar to a Software as a Service model, EaaS is a financing and ownership model that allows organizations to avoid capital expenditures and instead pay only for ongoing service and the associated resilience, reliability and sustainability performance attributes.

The EaaS model is similar to a Power Purchase Agreement contract, but in this case the customer contracts with a third-party microgrid services provider for a specified set of energy outcomes, backed by custom infrastructure deployment tailored to the businesses specific needs for resilience, reliability, sustainability and cost management. In addition to private funding, manufacturers should be aware of additional government funding and tax incentives that can further reduce the capital needed for energy infrastructure projects.

For example, there are several investment tax credits (ITC) that support microgrid development, such as the Waste-to-Heat-Power and Solar ITCs and others that have been recently introduced to Congress, including the Energy Storage Tax Incentive and Deployment Act and the MICROGRID Act. The American Jobs Plan proposes a ten-year extension and phase down of an expanded direct-pay investment tax credit and production tax credit for clean energy generation and storage, in addition to several grant programs to support the overarching goal to reach 100 percent carbon pollution-free electricity by 2035.

EaaS providers help customers capture the economic benefits of these opportunities, but more importantly, they help speed up projects by bringing direct capital investment and a focused approach on enhancing energy outcomes.

Conclusion

Under the Biden administration’s infrastructure framework, not only will manufacturing play a key role in producing the technologies needed for the energy transition, the industry itself must play a role in sustainable economic recovery. Just as U.S. manufacturing was the Arsenal of Democracy in World War II, it must be part of the arsenal in the fight against climate change today. Combining distributed energy resources with new public and private financing vehicles can help answer that call. In bringing together technical, financial and contractual capabilities, EaaS eliminates the risk and capital expense for manufacturers while meeting their current and future energy needs in an increasingly competitive and regulated business environment.

Contact Email:

alphastruxure@antennagroup.comAuthor biography:

Nicole Geneau is a leader with over 20 years of experience in clean energy, investment, commercialization of innovation and strategy. Nicole is SVP of Development for AlphaStruxure, a joint venture between The Carlyle Group and Schneider Electric that delivers custom Energy as a Service microgrid solutions. At AlphaStruxure, Nicole helps clients achieve sustainable, resilient, reliable and cost-effective energy, reducing risk and accelerating their core mission with no upfront cost.

Prior to AlphaStruxure, Nicole was Strategy and Market Development Director for Mortenson’s Integrated Energy Solutions business, actualizing electrification trends across the company’s commercial and energy operating groups, including electrified transportation systems, microgrids, distributed energy resources and utility grid modernization.

Nicole also brings extensive industry experience as a leader in large-scale renewable energy development. She was previously Development Director for NextEra Energy Resources where she was a key member of the team that delivered $2.5 billion of capital investment in renewable energy generation facilities in Canada.

Nicole is a Sloan Fellow in Leadership & Innovation from MIT, a Fellow in Economics of Energy from the UK Foreign & Commonwealth Office (University of Reading, UK) and has a Bachelor of Commerce from Queen’s University in Canada.