Microgrids can seem to be highly custom, with confusing definitions, and solar firms co-opting the name. As a customer looking to transform your energy picture to improve your company’s sustainability, business continuity, and energy costs, learning about Microgrids can be daunting; owning and operating them even more so. Microgrids are not magic but they are messy.

Just because something is messy, or hard to do, does not diminish its value to the customer.

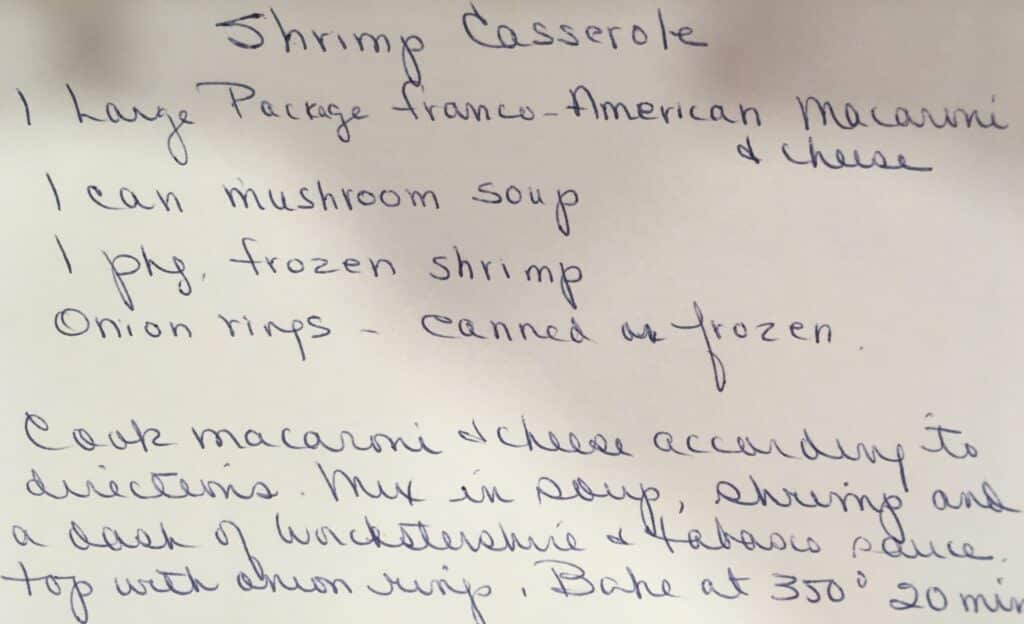

While a behind-the-meter (BTM) on-site energy solution (Microgrid) is not cookie-cutter, there is a fairly common “recipe” for success. The ingredients are generally the same every time, but the portions may be larger or smaller to fit the overall goal of the recipe which is to build something that delivers on the customer’s needs.

Now, looking for a good example of a recipe, I turned to one of my late mother-in-law’s recipe. Please notice there are multiple ingredients, not a single resource (ingredient) like solar-only on a site. There are specific proportions to create the flavor sought; probably from experience and that’s okay. You could double the size of one ingredient, but without doubling the remainder, there will be a different taste or outcome. This is true for Microgrids. You could over-size the combined heat and power (CHP) unit, but the performance of the system will not be optimal. Finally, you need clear directions for combining the ingredients. For Microgrids, this is the control system and optimization algorithms that run continuously. These controls can accommodate different ingredients, even different proportions.

So, what is the recipe for a behind-the-meter energy system, namely Microgrid?

Ingredient 1:

Customer objectives. Now this is a recipe within a recipe. Customers have a mixture of four objectives; (1) long-term cost predictability, (2) sustainability, (3) resilience, and (4) reliability. Each customer will assign specific relative importance of these four, but all will be in the mix. It is important to fully discuss and vet the objectives because different objectives are better served by some technologies over others.

Ingredient 2:

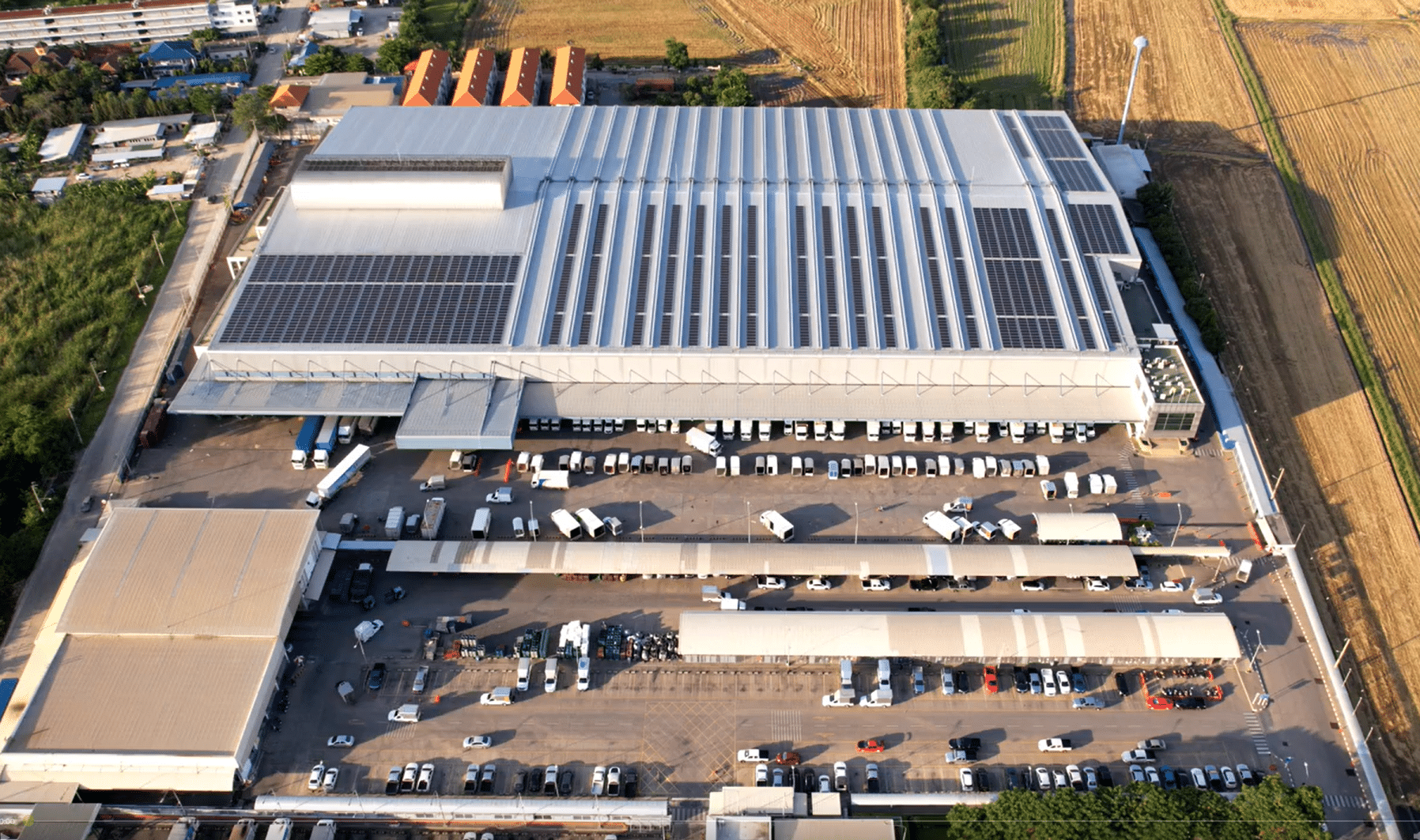

Understand the load (energy use) profile. It is important to understand the load profile from a day / night perspective as well as seasonal and weekday / weekend perspectives. Like objectives, different parts of a load profiles can be better served by certain technologies over others.

Ingredient 3:

Know the best fit comes from multiple resources. With knowledge of customer objectives and load profiles, a best fit of resources can be modeled. The resource mix generally includes; (1) a baseload generation source such as gas genset, CHP, or fuel cell; (2) a variable generation source that resembles the load profile most days such as solar PV; and (3) an energy storage resource that can bridge the baseload and variable generation sources as well as facilitate seamless transition to island mode and back to grid connection.

Ingredient 4:

Third-party capital. The customer often wishes to retain their capital budget for core mission; adding a new product, expanding production, R&D, etc. An energy transformation project often falls below the line because it is not core mission. In addition, most customers do not have a Microgrid-savvy workforce on staff, which can be a risk if trying to go it alone. This is where an energy as a service (EaaS) solution comes into play. An EaaS provider, like AlphaStruxure, not only provides the capital for the on-site energy project, it retains the risk associated with this messy but meaningful transformation. This will develop into a long-term trusted partner relationship.

Ingredient 5:

Take the O&M risk off the back of the customer. Along with the EaaS provider supplying the capital, it also handles the long-term operations and maintenance (O&M) support to the system and equipment. This makes it logical to combine the capital payback with the ongoing O&M support risk into a single energy services agreement (ESA) between the customer and the EaaS provider.

Ingredient 6:

Design for autonomous operations. The customer and EaaS provider are best served with a Microgrid control system capable of understanding the load and generation balance and taking action to maintain the balance. This is especially true when the grid is lost and/or off-site oversight is lost. This “default” operation assures that resilience and reliability are maintained for the customer to maximize business continuity.

Instructions:

Now, combine and cook. That is, design and engineer a technical solution around a thorough understanding of customer objectives and the load profiles. Size the resources not for the 1 peak demand hour per year, but for a resource mix that covers 90% of the hours per year. That last 10% is better handled by the grid, load management, and/or inherent flexibility in the Microgrid resource mix as directed by the Microgrid controls.

Build the capital expense and operational expense budgets to deliver the design, and demonstrate the economics to the capital provider; all to secure the capital.

Build the business case and risk transfer for the customer including the long-term O&M plan and secure the agreement with the customer.

Close the investment and go to work.

It sounds simpler than it is, but EaaS providers have developed the necessary skills and experience to create the customer value promised. There is a recipe and a process. Experience is developed, made repeatable by the recipe and following the instructions.